CVD diamond is Chemical Vapor Deposition synthetic single crystal diamond material.

CVD diamond is manufactured by means of a diamond synthesis technology in which a low pressure reactor is used to combine a thermal or plasma activating agent with a gas-phase carbon to produce a chemical reaction which results in polycrystalline

Properties

Vickers hardness 7000-10000 kg/mm2

Thermal Stability: ~1200˚C.

Density:3.51g/cm³

Young¡¯s modulus:1000-1100Gpa

Thermal conductivity: >8W/cm£®K

Chemical stability: insoluble in alkali and acid

Friction coefficient(contrary to the steel):<0.1

non-oriented

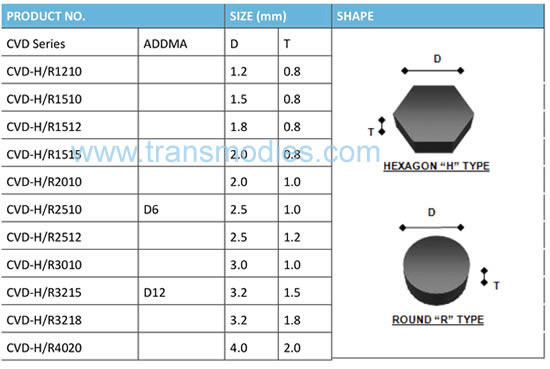

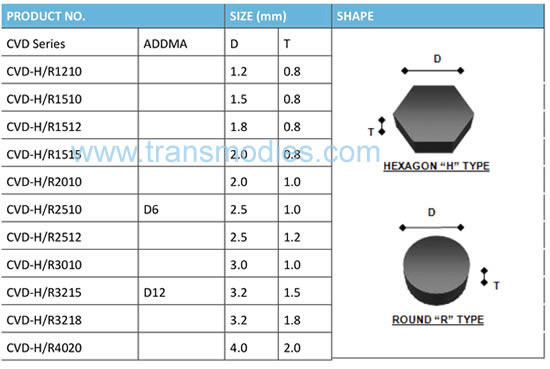

Hole size range

Semifinished:From 0.010mm to 0.800mm

Finished:From 0.020mm to 1.200mm

Advantage:

Wear resistance and temperature resistance are similar as ND,SMCD,better than PCD material.

Lower price that nature diamond dies.

No directional wear,because it's isotripic.

Applications

hard metal fine wire,tungsten wire, molybdenum & stainless steel wire,alloy wire,copper wire and other fine wire.

How to order our products.pdf How to order our products.pdf

|